PRODUCTS CENTER

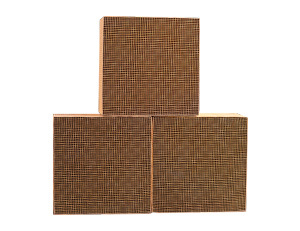

Indonesia VOCs precious metal honeycomb ceramic catalyst

Category:

IndonesiaProduct

Product Description

Product Overview

Precious metal catalysts are made of 1-2nm platinum-based highly active components, which are riveted onto a high specific surface area carrier through a unique process to create a broad-spectrum VOCs oxidation catalyst. The catalysts are combined with oxygen carriers to produce a broad-spectrum VOCs oxidation catalyst. The catalysts are highly stable, long-lived and cost-effective, and are suitable for CO and RCO catalytic combustion devices.

High adsorption capacity

The catalyst is made of 1--2nm Pt-based high activity component by special process, which improves the dispersion of the active component on the surface of the carrier.

Low reaction temperature

Nanoscale active component improves the dispersion of reactive sites, and the catalytic reaction temperature is lower.

High catalytic activity

The addition of rare earth co-catalyst realizes the characteristics of high oxygen storage, high specific surface area and high dispersion on the surface of catalyst, and improves the catalytic activity.

Technically Evaluated

Laboratory tests have shown that the efficiency of precious metal catalysts can reach 99% for conventional exhaust gases.

Technical Parameters

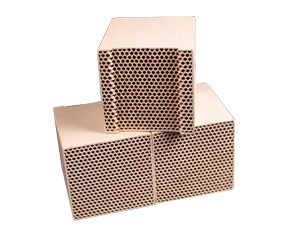

| Carrier | cordierite |

| Specification | 100*100*50 |

| Wall thickness | ≤0.2mm |

| Mesh | 200 mesh |

| Hole Type | square hole |

| Pressure Drop | 1080Pa/m |

| Pressure Resistance | A≥10Mpa,B≥2Mpa. |

| Specific heat capacity | 900-1000J/kg·K |

| water absorption | ≤23% |

| Specific surface area | 80-120m2/g |

| Precious metal content | ≤1200 Pt/Pd |

| Bulk density | 550kg/m3 |

| Effective cross-sectional area | >65% |

| Coefficient of thermal expansion | 4.5-5.4*10-6K-1 |

| Impact Temperature | 700℃ |

| Working Temperature | 500℃ |

| Air velocity | 10000h-1-15000h-1 |

| Concentration range | 1500mg/m3-6000mg/m3 |

| Dust content | ≤1mg/m3 |

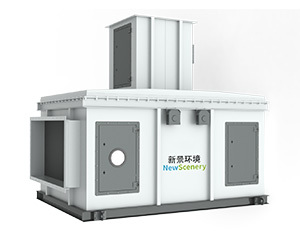

| Industry | Spraying, printing, chemical, etc. |

| Service life | ≥8500hours |

| Applicable V0Cs types | Broad-spectrum type (operating temperature adjusted according to components) |

| Main crystal phase | Y-A1203 |

| Conversion efficiency | ≥95% |

VOCs Conversion Rate-Temperature Trend Plot