Product

Contact Us

Contact:+86-18266440861

E-mail:newscenery@nshotmail.com

Address: 4666 Tianqu East Road, Decheng District, Dezhou City

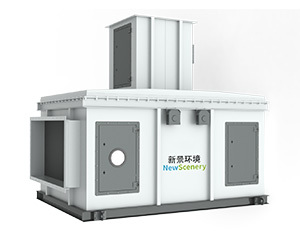

Zeolite molecular sieve wheel

- Commodity name: Zeolite molecular sieve wheel

- Description

-

Product introduction

Zeolite rotor is a kind of adsorption and concentration equipment, it uses its own high adsorption efficiency and fast desorption advantages of high air volume and low concentration concentration concentration, into low air volume and high concentration of organic waste gas, so as to reduce the investment cost of equipment and operating costs to achieve cost-effective organic waste gas treatment.

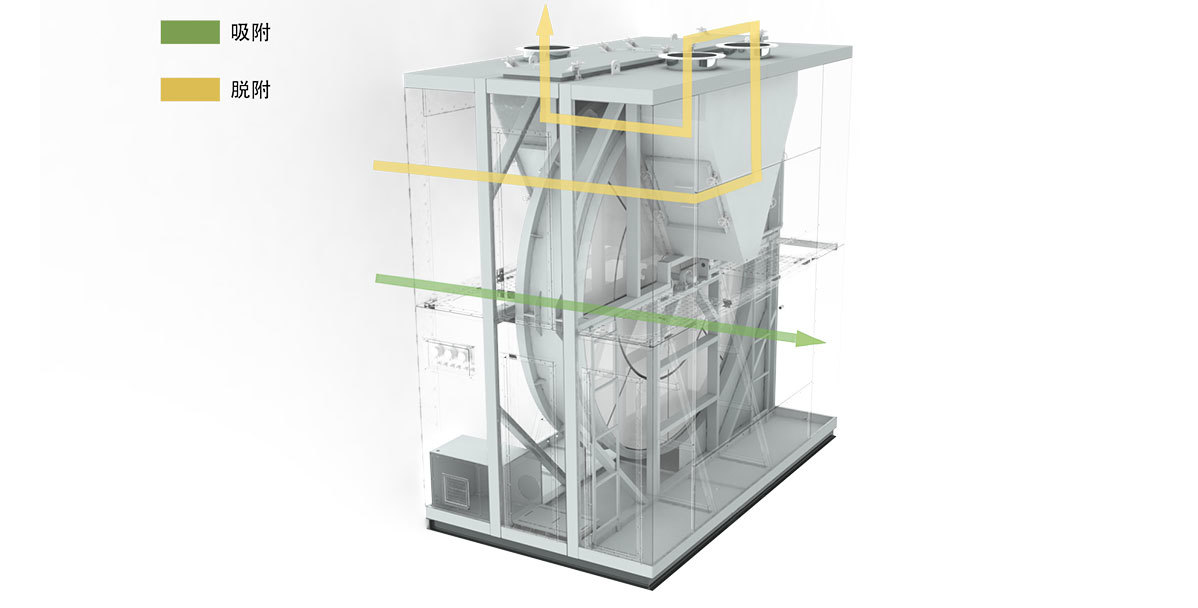

Zeolite rotor can realize continuous operation of adsorption-desorption-cooling compared with fixed bed. By heat-resistant, corrosion-resistant and abrasion-resistant sealing material will be zeolite runner separated into three parts, namely, large fan-shaped and two small fan-shaped part; large fan-shaped part of the adsorption area, can be adsorbed organic matter; two small fan-shaped part of the cooling area and high temperature desorption area.

Core competitive advantages

1. The pore size of the product is uniform, and the differential pressure is stable below 600 Pa, which reduces the incidence of hole plugging of the rotor.

2. Self-developed sintering process, through the control of the heating curve, so that the strength of the rotor module to improve 10%, adsorption capacity increased by 20% -30%, desorption time shortened by about 20%; greatly improve the performance of the rotor.

3. Provide whole system technical support for pretreatment and end combustion process paired with zeolite rotor.

4. Forming strategic cooperative relationships with environmental assessment organizations and third-party testing organizations, we are able to provide technical consulting before project initiation and testing services for the treatment efficiency of the project after completion of the project.

Working Principle

The zeolite rotor utilizes "adsorption-desorption-cooling" three-zone cycle operation mode, first of all, the large air volume of the adsorption fan to the workshop VOCs through the filtration box to filter out the large particles of material, and then adsorbed through the zeolite rotor, through the zeolite rotor of the gas can be discharged directly.

Adsorption of a large number of VOCs zeolite wheel into the high-temperature desorption area, small air volume of hot air gas (temperature of about 220 ℃) will be adsorbed on the zeolite wheel VOCs molecules converted into a high concentration of waste gas, the concentration of multiples of general 5 ~ 30 times. After the adsorption is completed, the desorption fan is used to send it to the back-end CO system or RTO system for combustion treatment, and the high-temperature gas generated by oxidation is used as regeneration air after heat exchange to achieve energy-saving effect.

Product Selection Chart

Remarks: Conventional treatment air volume refers to the range of exhaust air volume that can be treated at both high and low concentrations. Limit air volume refers to the maximum air volume when the exhaust gas is in low concentration (concentration ≤ 300mg/㎡). (For specific projects, we will decide the type of rotor to be used through experimental data.)

Product characteristics

1. Zeolite rotor has a long service life of 5-10 years. 2.

2. the pressure drop generated by adsorption of VOCs is very low, which reduces the energy consumption of the fan.

3. 5-30 times of concentration, energy saving and high efficiency, lower operating costs. 4.

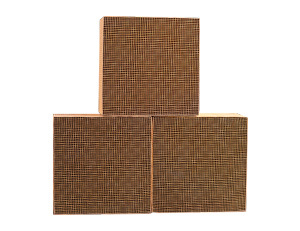

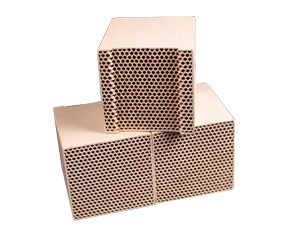

4. zeolite rotor adopts honeycomb structure, higher specific surface area using inorganic materials, with non-combustible characteristics.

5. the exhaust gas after concentration has high adsorption efficiency, the adsorption efficiency is ≥90%, the highest can reach more than 98%, which can meet the national and regional emission standards.

Product Parameters

Corrugated Height 1.6mm Corrugated width 3.2mm Adsorption bed thickness 400mm/500mm/600mm Adsorption temperature ≤40℃ Adsorption humidity ≤75% Zeolite content 40%-70% Adsorption wind speed 2.0-3.5m/g Desorption wind speed ≥3m/g Rotation speed 1-6r/h Concentration 5-30x Desorption temperature 180-220℃ Purification efficiency ≥90%, up to 98% or more Sealing strand Herringbone Fluoroelastomer Remarks Rotor module performance parameters with zeolite module performance parameters Shipping Video

Qualification Honor

Key words:

Related Products