Product

Contact Us

Contact:+86-18266440861

E-mail:newscenery@nshotmail.com

Address: 4666 Tianqu East Road, Decheng District, Dezhou City

With the application of modern production technology and the breakthrough of catalyst theory, a kind of advanced catalytic technology that can greatly improve the conversion rate of chemical reaction and enable the reaction to be carried out under milder conditions has been catalyzed - adiabatic membrane catalytic technology The catalytic membrane used in this technology is a high-entropy alloy ceramic membrane grown on 304 stainless steel wire mesh as the base frame through the in-situ growth technology, which is suitable for the treatment of many kinds of VOCs gases, and can be used to Replace precious metal catalyst; in the reduction reaction, the processing efficiency is better than precious metal catalyst.

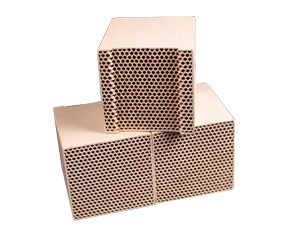

VOCs precious metal honeycomb ceramic catalyst

Precious metal catalysts are made of 1-2nm platinum-based highly active components through a special process, riveted onto a high specific surface area carrier. The catalysts are combined with oxygen carriers to produce a broad-spectrum VOCs oxidation catalyst. The catalyst has high stability, long life and cost-effective advantages and is suitable for C0 and RC0 catalytic combustion devices.

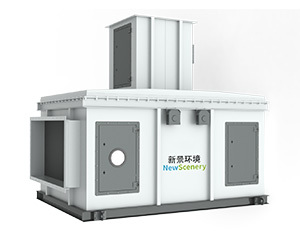

Zeolite rotor is a kind of adsorption and concentration equipment, it uses its own high adsorption efficiency and fast desorption advantages of high air volume and low concentration concentration concentration, into low air volume and high concentration of organic waste gas, so as to reduce the investment cost of the equipment and operating costs to achieve cost-effective organic waste gas treatment.

Non-precious metal honeycomb ceramic catalysts

The transition metal catalyst is based on nanosilver as the main active component, and the stability of nanosilver is improved by introducing Cu and Mn components into the carrier. This catalyst is not suitable for high temperature, and it has a very high activity for alcohol ether ester organic waste gas.

Anti-sulfur and anti-chlorine catalyst

The company is committed to providing cost-effective materials, core components, specialized equipment and VOCs waste gas treatment solutions and technical support.

The company is committed to providing cost-effective materials, core components, specialized equipment and VOCs waste gas treatment solutions and technical support.

Honeycomb zeolite molecular sieve

Honeycomb zeolite molecular sieve carrier has uniform microporous, its pore size is comparable to the size of general molecules, it is an inorganic microporous material composed of SIO₂/AI₂O₃ and alkali metal or alkaline earth metal, the specific surface area of 300-800 square meters/g, it has the characteristics of high temperature resistance, non-flammable, good thermal stability and hydrothermal stability, and so on.

沸石转轮分为盘式和筒式,两者的吸附床层均由特定形状的沸石模块组成。沸石模块以改性沸石为原料,以陶瓷纤维为骨架,加工成方形蜂窝块,是一款高性能吸附产品,能够有效吸附有机废气。

The company is committed to providing cost-effective materials, core components, specialized equipment and VOCs waste gas treatment solutions and technical support.

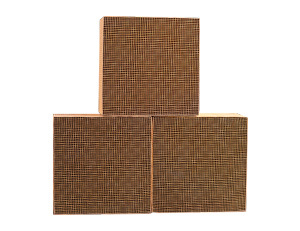

Honeycomb activated carbon can be widely used in a variety of gas purification equipment and exhaust gas treatment project, practice has proved that the purification effect is better than ordinary.

Through high-temperature activation, the surface microstructure of the mesh membrane is designed and manufactured so that the adsorbed VOCs molecules can be desorbed by the small air volume of high-temperature gas in a shorter time.

Zeolite rotor is a kind of adsorption and concentration equipment, it uses its own high adsorption efficiency and fast desorption advantages of high air volume and low concentration concentration concentration, into low air volume and high concentration of organic waste gas, so as to reduce the investment cost of the equipment and operating costs to achieve cost-effective organic waste gas treatment.