Product

Contact Us

Contact:+86-18266440861

E-mail:newscenery@nshotmail.com

Address: 4666 Tianqu East Road, Decheng District, Dezhou City

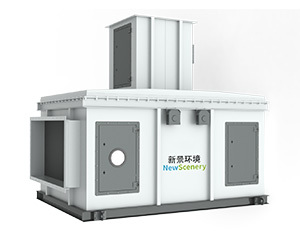

Zeolite molecular sieve drum

- Commodity name: Zeolite molecular sieve drum

- Description

-

Product introduction

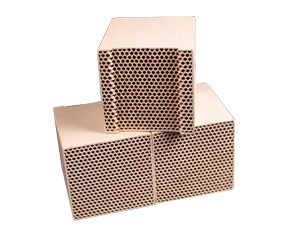

Exhaust gas passes through the inside of the zeolite rotor, the VOCs components are adsorbed by the zeolite molecular sieve, and with the help of the induced draft fan inside the system, the purified clean gas is discharged directly. The concentration factor can reach 10-50 times, which greatly reduces the late equipment investment and operating costs, and is more suitable for intermittent working conditions compared with the disk rotor.

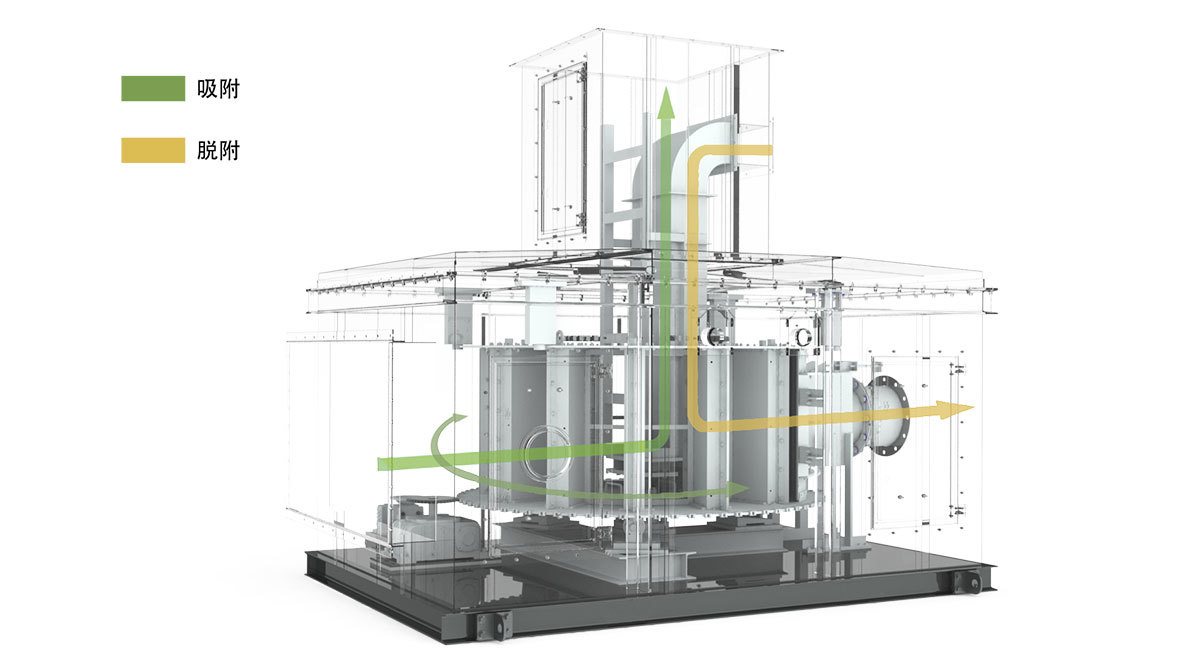

Working Principle

The zeolite rotor is divided into 3 areas by the special sealing device: adsorption area, regeneration area and isolation area (some process features only two parts: adsorption area and regeneration area). Organic waste gas through the pretreatment filtration to remove paint mist, dust and miscellaneous and water vapor, through the slow rotation of the zeolite rotary adsorption bed, the waste gas uniformly through the rotating bed section, organic waste gas pollutant molecules are adsorbed, the gas is purified and discharged. Subsequently, the adsorbent rotates to the regeneration area, where it is desorbed and regenerated in contact with high-temperature air, and then rotates to the adsorption area to be adsorbed again. With the rotation of the rotating cylinder, the zeolite rotating cylinder adsorption bed periodically carries out adsorption and desorption, realizes the purification of organic waste gas, and ensures continuous and stable operation.

Product Advantages

High processing efficiency

Independent research and development of modified molecular sieve and rotating cylinder module formula, greatly improve the VOCs waste gas adsorption capacity, processing efficiency is as high as ≥ 90%.

Modularization

The rotating cylinder adopts modular design, which is more convenient for disassembling and replacing.

High concentration rate

The unique design of the rotor has a higher concentration ratio than the rotor.

Fast desorption speed

Through high-temperature activation, the surface microstructure of the mesh membrane is designed and manufactured, so that the adsorbed VOCs molecules can be desorbed by the high-temperature gas with small air volume in a shorter time.

High hydrophobicity

Selection of molecular sieves with high silica-aluminum ratio, stronger hydrophobicity, able to cope with more severe working conditions.

Transmission and sealing

Stable transmission system, can detect the speed, with shutdown protection. High sealing efficiency, good material, good installation, out of the maintenance period after the replacement price is the lowest in the market.

Shipping Video

Qualification Honor

Key words:

Related Products