NEW SCENERY

Key words:

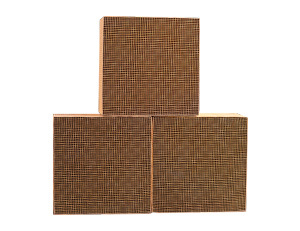

With the application of modern production technology and the breakthrough of catalyst theory, a kind of advanced catalytic technology that can greatly improve the conversion rate of chemical reaction and enable the reaction to be carried out under milder conditions has been catalyzed - adiabatic membrane catalytic technology The catalytic membrane used in this technology is a high-entropy alloy ceramic membrane grown on 304 stainless steel wire mesh as the base frame through the in-situ growth technology, which is suitable for the treatment of many kinds of VOCs gases, and can be used to Replace precious metal catalyst; in the reduction reaction, the processing efficiency is better than precious metal catalyst.

Key words:

Zeolite rotor is a kind of adsorption and concentration equipment, it uses its own high adsorption efficiency and fast desorption advantages of high air volume and low concentration concentration concentration, into low air volume and high concentration of organic waste gas, so as to reduce the investment cost of the equipment and operating costs to achieve cost-effective organic waste gas treatment.

Key words:

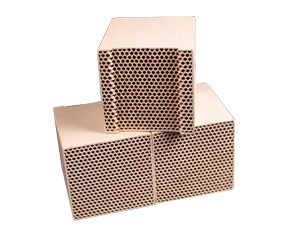

Non-precious metal honeycomb ceramic catalysts

The transition metal catalyst is based on nanosilver as the main active component, and the stability of nanosilver is improved by introducing Cu and Mn components into the carrier. This catalyst is not suitable for high temperature, and it has a very high activity for alcohol ether ester organic waste gas.

Key words:

Anti-sulfur and anti-chlorine catalyst

The company is committed to providing cost-effective materials, core components, specialized equipment and VOCs waste gas treatment solutions and technical support.

Key words:

Is there a need to focus on monitoring and treating VOCs in winter?

VOCs refers to a variety of organic compounds at room temperature, boiling point of 50 degrees Celsius to 260 degrees Celsius, these compounds have two characteristics, one is volatile or semi-volatile at room temperature, and second, there are thousands of species. The volatility increases as the temperature rises, so that emissions of VOCs are significantly higher in summer than in winter.

Key words:

Application of zeolite molecular sieve in VOCs treatment

Feature 1.Through the extremely regular connection of silica and alumina, the micropores of the zeolite molecular sieve formed are homogeneous, which makes its adsorption selective and the adsorption efficiency of target pollutants greatly improved.

Key words:

9 Safety Recommendations for Activated Carbon VOCs Exhaust Adsorption Units

When we understand the risk of activated carbon VOCs adsorption device, according to the actual situation, can be targeted, take some targeted measures. In general, from the perspective of preventing the formation of the three elements of combustion, from the source design, engineering and management measures to go up to the force, and ultimately can be adsorption device risk down to an acceptable range. The following are some suggested measures:

Key words:

What are the factors that affect the adsorption performance of VOCs?

VOCs adsorption materials are various, such as activated carbon, zeolite and so on. The adsorption and desorption performance of adsorbent materials for VOCs is affected by a variety of factors, the main influencing factors include the structural parameters of the adsorbent, the nature of the molecules of the VOCs gas, and the external conditions, etc., which are explained in detail below:

Key words:

How to choose high quality activated carbon?

According to the "People's Republic of China Air Pollution Prevention and Control Law" Article 108 of the provisions of the production and service activities containing volatile organic compounds waste gas, not in accordance with the provisions of the installation and use of pollution prevention and control facilities, by the people's government at or above the county level of the competent department of ecological and environmental protection ordered to make corrections, and impose a fine of more than 20,000 yuan to 200,000 yuan; refusal to make corrections, and ordered to shut down and rectify the situation.

Key words:

Activated carbon adsorption is a method more commonly used by industrial enterprises to treat volatile organic compounds (VOCs). It is widely used because activated carbon has the following characteristics: 1. Activated carbon has a large specific surface area and adsorption capacity, good mechanical strength, chemical stability and thermal stability, and can be repeatedly regenerated. 2. According to different forms, activated carbon can be divided into granular activated carbon, honeycomb activated carbon and powder activated carbon, which can be applied to different process conditions.

Key words:

How to choose a suitable for you?

Let us assist you!

Our experts will contact you as soon as possible to meet your needs.

Latest Products

Latest News