(Environmental Protection Tips) Activated Carbon Treatment Process Standardized Management Guidelines

Release time:

2023-07-14

Activated carbon adsorption is a method more commonly used by industrial enterprises to treat volatile organic compounds (VOCs). It is widely used because activated carbon has the following characteristics:

1. Activated carbon has a large specific surface area and adsorption capacity, good mechanical strength, chemical stability and thermal stability, and can be repeatedly regenerated.

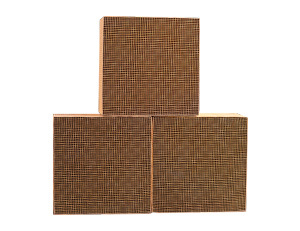

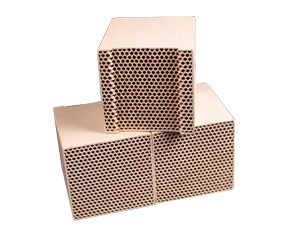

2. According to different forms, activated carbon can be divided into granular activated carbon, honeycomb activated carbon and powder activated carbon, which can be applied to different process conditions.

Self-inspection guide for standardized management of activated carbon adsorption treatment process of gas-related enterprises

01 Design air volume

VOCs-related emission processes should be operated in a confined space or collected using a fully enclosed gas collection hood, which cannot be confined using a local gas collection hood, should reasonably select the collection points according to the characteristics of exhaust emissions, set up a gas collection hood that can effectively collect exhaust gases in accordance with the provisions of the "Classification and Technical Conditions of Exhaust Hoods" (GB/T 16758), and the position of the farthest from the open surface of the hood for the unorganized emission of VOCs, the control wind speed is Not less than 0.3 meters/second.

The fan of the activated carbon adsorption device shall meet the air volume required based on the shape, size and quantity of the air collection hood and the control air speed of the workshop, and if it fails to meet the requirements, it shall be reformed by replacing the high-power fan, installing additional flue fans, and increasing the drapery.

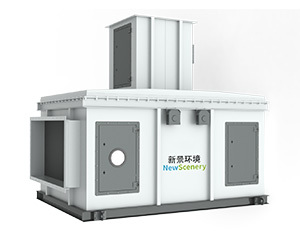

02Equipment quality

The internal structure of horizontal activated carbon tanks and box-type activated carbon tanks should be reasonably designed, with smooth gas circulation, no short-circuit and no dead corner. The doors, welds and pipe connections of the activated carbon adsorption device should be tightly closed without gas leakage, and all the bolts and nuts should be surface-treated and firmly connected. The shell of the device made of metal should be made of stainless steel or anticorrosive treatment, and the surface should be smooth without rust, burr, unevenness and other defects.

Discharge fan should be installed at the back end of the adsorption device, so that the device to form a negative pressure, as far as possible to ensure that no contaminated gas leakage to the outside of the equipment box tank body.

Sampling ports should be set up on the inlet and outlet pipes of the activated carbon adsorption device, and the sampling port settings should be in line with the requirements of "Technical Requirements for Environmental Protection Products Industrial Exhaust Gas Adsorption and Purification Devices HJ/T 386-2007", so as to facilitate the daily monitoring of the adsorption efficiency of activated carbon. Replace the activated carbon in time according to the activated carbon replacement cycle, and the replaced activated carbon is treated as hazardous waste.

03Gas flow rate

The gas flow rate of the adsorption layer of the adsorption device should be determined according to the morphology of the adsorbent. When granular activated carbon is used, the gas flow rate should be lower than 0.60m/s, and the thickness of loading should not be lower than 0.4 m. The activated carbon should be loaded neatly to avoid short-circuiting of the gas flow; when activated carbon fibers are used, the gas flow rate should be lower than 0.15m/s; and when honeycomb activated carbon is used, the gas flow rate should be lower than 1.20m/s.

04 Exhaust gas pretreatment

The particle content and temperature of the waste gas entering the adsorption equipment should be lower than 1mg/m³ and 40℃ respectively; if the particle content is more than 1mg/m³, it should be pre-treated by filtration or washing first.

The adsorption effect of activated carbon on acidic waste gas is poor, and the acidic gas is easy to cause corrosion of the equipment body, it should be pre-treated by washing first.

Enterprises should formulate equipment operation and maintenance procedures for regular replacement of filter materials to ensure that the activated carbon is used under conditions of low particulate matter and low water content.

05 Quality of activated carbon

The transverse compressive strength of honeycomb activated carbon shall be not less than 0.9MPa, the longitudinal strength shall be not less than 0.4MPa, the iodine adsorption value ≥650mg/g, the specific surface area ≥750m2/g. Activated carbon fibers shall have a specific surface area of not less than 1,100m2/g (BET method).

Enterprises should prepare the purchased activated carbon manufacturers on the iodine value of activated carbon, specific surface area and other product quality certification materials for inspection.

06 Activated carbon filling amount

The ratio of the filling volume of cellular activated carbon to the volume of exhaust gas treated per hour is 1:5000, i.e. every 5000m³ of air volume needs to be filled with no less than 1m³ of cellular activated carbon. According to the actual research and accounting, the saturation adsorption capacity of good quality honeycomb activated carbon for VOCs-related processes is 5-8% of its own weight, and if the filling volume is less than 1:5000, it will affect the adsorption and purification efficiency and the replacement cycle. The replacement cycle of activated carbon generally should not exceed 3/4 months.

07Standardize enterprise environmental protection management

Activated carbon adsorption and treatment device should be opened before the production process equipment to generate exhaust gas, later than the production process equipment shutdown, and encourage the realization of the conditions and the production device chain control. Activated carbon adsorption device should be set up nameplate and posted in the device in a conspicuous position (can refer to the outfall setup specifications), including the name of the environmental protection products, model, air volume, name of activated carbon, filling volume, filling mode, iodine value of the activated carbon, the specific surface area and other content. Enterprises should make daily operation and maintenance ledger records of activated carbon adsorption, mainly including equipment operation start and stop time, equipment operation parameters, consumption of consumables (purchasing volume, usage volume, loading volume, replacement volume and replacement time, disposal records, etc.) and energy consumption (power consumption).

In practice, safety production requirements should be strictly enforced and the activated carbon treatment process should be standardized and operated.

Not supporting the construction of waste gas treatment facilities for enterprises ordered to stop production, rectification; in addition to malodorous odor treatment, new enterprises are not allowed to use a single low-temperature plasma, photo-oxidation, water spraying, and other inefficient end-of-pipe treatment technology, the existing enterprises should be replaced as soon as possible for high-efficiency treatment processes (eg, combustion technology, etc.) or the use of a variety of combined processes for transformation.

More information

How to choose high quality activated carbon?

2023-08-02