How to choose high quality activated carbon?

Release time:

2023-08-02

According to the "People's Republic of China Air Pollution Prevention and Control Law" Article 108 of the provisions of the production and service activities containing volatile organic compounds waste gas, not in accordance with the provisions of the installation and use of pollution prevention and control facilities, by the people's government at or above the county level of the competent department of ecological and environmental protection ordered to make corrections, and impose a fine of more than 20,000 yuan to less than 200,000 yuan; refused to make corrections, and ordered to shut down and rectify the situation.

How much do you know about activated carbon?

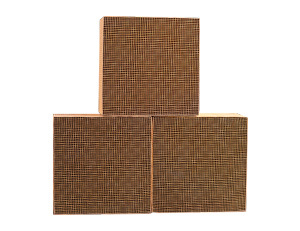

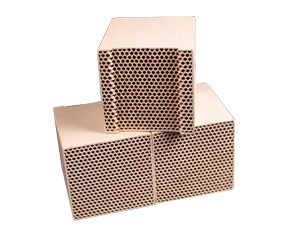

Activated carbon, also known as activated carbon black, is a kind of carbon material after crushing, sieving, activation, screening and a series of processes.

With excellent adsorption properties and stability, its main component is carbon, containing a small amount of oxygen, nitrogen, hydrogen, sulfur and other elements, has a strong adsorption and purification capacity, can effectively adsorb all kinds of organic and inorganic pollutants in the gas-phase and aqueous-phase environments, is widely used in the field of medicine, chemical industry, food, environmental protection governance, etc., used for decolorization and deodorization, purification of wastewater, and the adsorption of formaldehyde, VOCs, soot, and other harmful substances.

Although the strong adsorption capacity of activated carbon for enterprises to solve the industrial production process of wastewater and waste gas treatment and other issues, but after many adsorption reaction of activated carbon, the internal chemical changes and structural changes will lead to the activation of activated carbon activity decreases, the specific surface area decreases, the adsorption capacity can not meet the needs of the production and become waste activated carbon.

The shape, quality and size of the activated carbon on the market are not the same, from the surface, nothing more than a black paste particles of material how to distinguish the quality of good and bad? Today, Xinjing Environment will explain to you.

At present, consumers do not know enough about activated carbon, often without activation of bamboo charcoal, charcoal, coconut shell charcoal and other carbonized material is mistaken for activated carbon; followed by low adsorption value of charcoal carvings, ordinary activated carbon is regarded as high-quality activated carbon.

Here we come through the "see, touch, weigh, try, test" to determine the quality of the activated carbon we buy.

Look

①Look at the volume

The strong adsorption of activated carbon is because it has many pores, and the more pores, the more fluffy the activated carbon will be, and the lighter the weight. Therefore, good quality activated carbon, in the case of the same weight package, the performance of the activated carbon will be much larger than the volume of poor-quality activated carbon.

②Look at the particle size

The smaller the particles of activated carbon, the larger the air contact area, the better the adsorption effect. It is recommended not to buy activated carbon with particles larger than 2mm. The smaller the particles of activated carbon, the larger the specific surface area, the better the adsorption effect. However, small particles of activated carbon, the production process loss is large, the dust generated is also more, so many manufacturers in order to reduce costs, the use of large particles of activated carbon, the effect is very poor.

③Look at the outer package

The packaging of activated carbon must be sealed, and the iodine adsorption value, specific surface area, factory information and other basic information of activated carbon must be clearly written on the packaging, otherwise it is difficult to judge whether the activated carbon is good or bad.

Touch

During the production process of activated carbon, the dust produced by the activated carbon will be treated. If there is too much dust, the activated carbon is easy to get dirty when you hold it in your hand, and it will also be harmful to the human body if inhaled.

At present, low-quality activated carbon on the market in order to reduce the cost, the hardness is greatly reduced, and at the same time, there is no de-powdering and de-dusting of the activated carbon, so friction with each other will produce a large amount of fine powder, dust is very heavy, and it will be very dirty to use, and it will also dirty the surrounding items.

Weighing

The higher the adsorption capacity of activated carbon, the more pores, the more fluffy the activated carbon, and the lighter the relative density will be. Therefore, good activated carbon will feel lighter, and in the case of the same weight package, the performance of good activated carbon will be much larger than the volume of poor quality activated carbon.

Test

Method one:

Put a small amount of activated carbon into the water, due to the penetration of water, the water will gradually immerse into the pore structure of the activated carbon, forcing the air in the pores to be discharged, thus generating a series of extremely small bubbles, pulling out a thin line of bubbles in the water, and at the same time, it will emit a silky bubbling sound.

The more intense this phenomenon occurs and the longer it lasts, the better the adsorption of activated carbon.

Method two:

Activated carbon has the special ability to turn colored liquids into light or colorless ones. You can try it with a small sample. Take two shiny cups, put pure water in one, and then put a drop of red ink (here, any pigment that is easy to examine but does not change the nature of water will do, such as blue ink, printer's colored ink, but not ink and carbon ink).

After mixing well, pour half of the colored water into another cup for comparison. Place the activated carbon into the colored water in an amount that is more than half of the water so that the effect is noticeable. After standing for 10-20 minutes, compare with the control water sample.

Under the same conditions, the stronger the decolorization effect, the better the adsorption of activated carbon.

Measurement

Method one:

Commission a qualified unit to monitor the purchased activated carbon according to the relevant national standards and provide the corresponding monitoring report.

Method two:

Before purchasing activated carbon, ask the manufacturer to provide corresponding test reports or product quality certificates.

What are the common adsorption indexes of activated carbon?

Iodine adsorption value, carbon tetrachloride (CTC) adsorption value, and methylene blue adsorption value. Iodine adsorption value is used to indicate the adsorption capacity of activated carbon on liquid substances, carbon tetrachloride adsorption value is used to indicate the adsorption capacity of activated carbon on gaseous substances, and methylene blue adsorption value is used to indicate the ability of activated carbon to decolorize.

The higher these three indexes are, the stronger the adsorption capacity of activated carbon is. So it is not that the higher the iodine adsorption value of activated carbon must be the better, but also depends on other indicators.

It is understood that the current market of poor-quality charcoal ash is high, high density, filled with the same volume of charcoal box, the weight is much greater than high-quality charcoal, so from the cost of transportation, the purchase expenditure may not be much cheaper than high-quality charcoal. Secondly, waste low-quality charcoal can only be disposed of harmlessly, plus the weight is heavier and the disposal fee is higher. Waste high-quality charcoal can be disposed of harmlessly and free of charge, or it can be reused after desorption. According to the calculations of relevant organizations, the exhaust gas adsorption efficiency of high-quality charcoal is at least 4 times higher than that of low-quality charcoal.

As an example

At present, many poor quality activated carbon (iodine adsorption value of 200) will be passed off as high quality activated carbon (iodine adsorption value of 650 or more), the price of which is between 3,000 and 5,000, but in fact, compared with the high quality of activated carbon, the final disposal cost and transportation cost is about 30%-40% more expensive. For the same airflow rate, the adsorption effect of poor quality carbon (iodine adsorption value 200, specific surface area 120) is about 7 times worse than that of high quality carbon (iodine adsorption value 800, specific surface area 850).

On the whole, from the point of view of the total cost of purchase and disposal of the two kinds of activated carbon, high quality carbon is obviously more cost-effective. Preliminary estimates from market research suggest that using high quality carbon can reduce costs by at least 20% compared to poor quality carbon.

More information

How to choose high quality activated carbon?

2023-08-02