PRODUCTS CENTER

Vietnam AMCR

Category:

VietnamProduct

Product Description

Product Overview

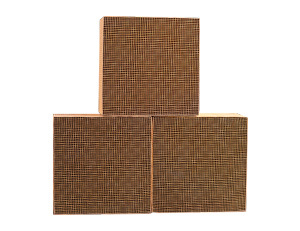

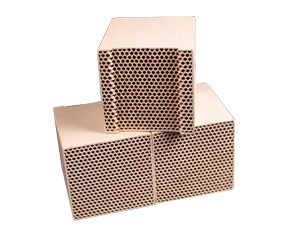

With the application of modern production technology and the breakthrough of catalyst theory, a kind of advanced catalytic technology that can greatly improve the conversion rate of chemical reaction and enable the reaction to be carried out under milder conditions has been catalyzed - adiabatic membrane catalytic technology The catalytic membrane used in this technology is a high-entropy alloy ceramic membrane grown on 304 stainless steel wire mesh as the base frame through the in-situ growth technology, which is suitable for the treatment of many kinds of VOCs gases, and can be used to Replace precious metal catalyst; in the reduction reaction, the processing efficiency is better than precious metal catalyst.

Product Benefits

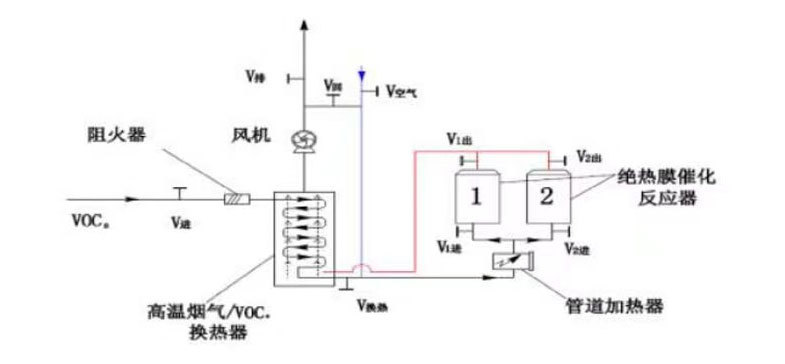

Adiabatic membrane catalytic purification of VOCs process flow

Stability

Resistant to acid and alkali, organic solvents, high temperature and high pressure

High efficiency

Reaction reaches "super flat", high selectivity and conversion rate.

Energy saving

Lower ignition temperature, energy consumption is 20% lower than traditional co under the same conditions.

No by-products

No oxides of nitrogen for nitrogenous voc by-products.

Safety and explosion-proof

Membrane catalytic reactor is equivalent to explosion-proof boom type flame arrestor, the fire extinguishing time in the membrane reactor is less than the ignition delay time of hydrocarbon, and the gas in the reactor is dispersed uniformly, and there is no heat storage function in the carrier, so it is more safe for the high-concentration exhaust gas. (The specially designed membrane catalytic reactor has been tested in the laboratories of Japan Research Institute of General Industry, Oxford University, Massachusetts Institute of Technology, and the U.S. Atomic Energy Commission for 13,000 hours, and its explosion-proof performance can meet the oxidizing reaction of oxygen and hydrogen within the explosion limit.)

Product Parameters

| vector (epidemiology) | 304 stainless steel |

| table of contents | 600 mesh |

| Resistant to dust | 1mg/m³ |

| Conversion efficiency | 99% |

| operating temperature | 260-600℃ |

| service life | 5-8year |

| thicknesses | 0.22mm |

| airspeed | 100000h-1 |

| compressive strength | 10Mpa |

| active ingredient | 3d overmetal |

| packing density | 7.9g/cm³ (no upper limit for nitrogen-containing voc) |

| Concentration range | 0-10000mg/m³ |

| Applicable vocs | Amides, benzenes, esters, etc. (S, C1 free) |

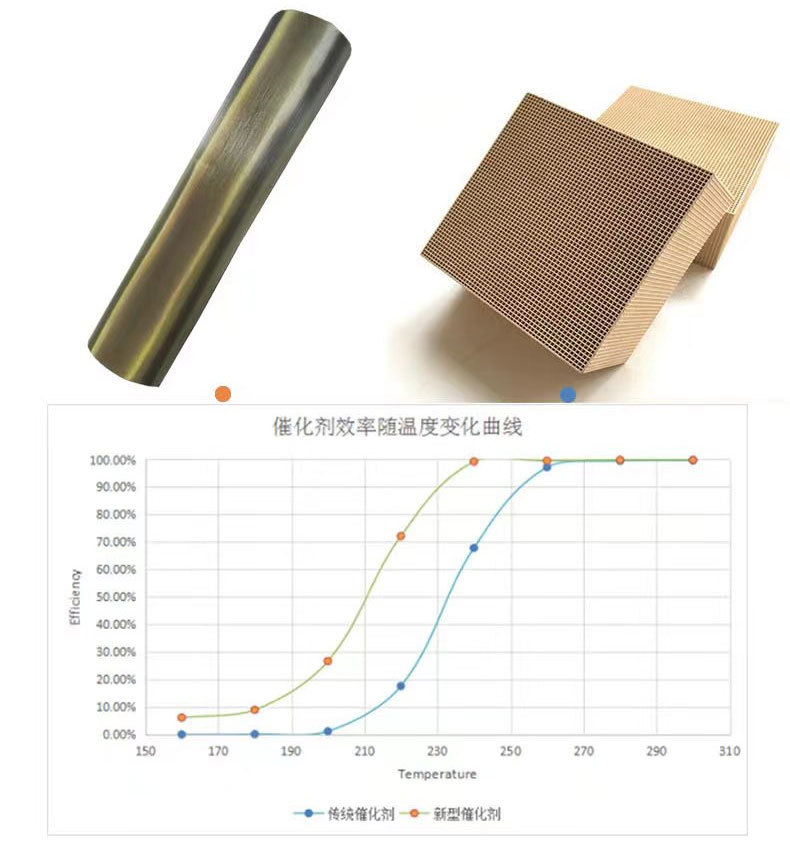

data comparison

Application Industries

Paint spraying and coating, printing and dyeing, rubber industry, pharmaceutical industry, chemical industry, electronic industry, and other industries.